YOUR IDEAS, PRECISELY MADE TO ORDER

Cutting-Edge Technology, Unrivaled Precision

No matter your project’s plastics machining needs, K&E has a solution. Our extensive inventory of American-made CNC machinery solves your project’s biggest machining challenges. With a variety of cutting-edge machines and over 50 years of experience crafted into every part we make, we deliver businesses— from multinational conglomerates to individual inventors— reliable plastics products with unrivaled precision.

CNC MACHINERY

If you have a need, we have the machine. K&E uses equipment with probe systems to ensure quick set-ups, quality parts, and accurate turnaround times. With K&E, you get the integrity of cutting-edge CNC machinery and the peace of mind that comes with American-made quality.

K&E CNC machining services include precision milling of plastic parts quickly and accurately on American-made machines.

- Variety of Haas® CNC Vertical Mills

- Haas® HRT 210 Rotary Tables for 4th axis capabilities

- Bridgeport® Miller

Our American-made lathes provide high-quality turning for your plastics parts.

- Haas® SL-20 CNC Lathe

- Haas® SL-20 BB CNC Lathe with Live Tooling

- Haas® ST-30 BB Lathe

- Haas® TL-3 CNC/Manual Tool Room Lathe

- Haas® OL-1 with Live Tooling

- SouthBend® 14-Inch Gap Engine Lathe

- Tsugami CNC Swiss Lathe Model #S205

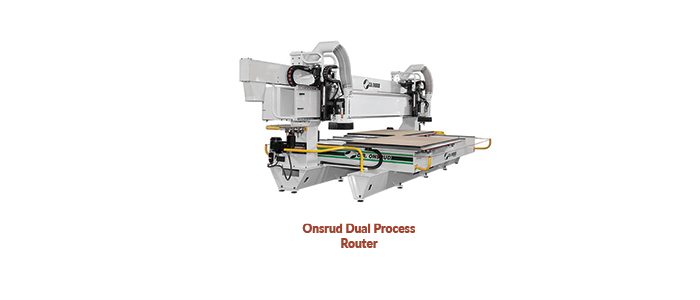

Our variety of routers are American-made with varying z-axis and fixturing capabilities including vacuum, vise, or custom.

- Haas® GR-408 Gantry Router

- Haas® GR-510 Gantry Router

- Haas® GR-510 Gantry Router with Extended Z-Axis

- Onsrud Dual Process Router

![]()

Milling

K&E CNC machining services include precision milling of plastic parts quickly and accurately on American-made machines.

![]()

Turning

Our American-made lathes provide high-quality turning for your plastics parts.

![]()

Routing

Our variety of routers are American-made with varying z-axis and fixturing capabilities including vacuum, vise, or custom.

PLASTICS MATERIALS

When we save, you save. In addition to CNC machines, we have a full arsenal of tools for a variety of material and plastics machining combinations. Our efficiency and extensive care in producing less waste of both time and materials passes those savings onto you.

K&E Plastics has over 50 years of experience working with thermoplastics, high-performance engineered polymers. Within the thermoplastics family, we machine virgin, glass-filled, or grades with other fillers. Our machinists ensure the proper coolants are used for the type of material they are machining.

Why use thermoplastics? They come in wide varieties compatible with specific mechanical, electrical, or chemical properties, enabling them to fit an extensive range of applications. Thermoplastics provide your project with the following benefits:

- Chemical resistant

- Eco-friendly manufacturing options

- Electrical insulation

- Elimination of lubrication

- Faster operation of equipment/ line speeds

- High strength and rigidity

- Impact resistance

- Less power needed to run equipment

- Longer part life

- Low coefficient of friction

- Low dissipation factor

- Low moisture absorption

- Reduced wear on mating parts

At K&E, we machine all types of composite grades including fiberglass-reinforced polyesters, paper-based laminates, and glass fabric laminates to name a few.

Why use thermosets? They are the perfect option for applications demanding the following capabilities:

- Economical

- Electrical insulation

- Excellent wear properties

- Flexible design

- Heat-resistant

- Lighter weight ratio than metal

- Superior dimensional stability

Thermoplastics

K&E Plastics has over 50 years of experience working with thermoplastics, high-performance engineered polymers. Within the thermoplastics family, we machine virgin, glass-filled, or grades with other fillers. Our machinists ensure the proper coolants are used for the type of material they are machining.

Why use thermoplastics? They come in wide varieties compatible with specific mechanical, electrical, or chemical properties, enabling them to fit an extensive range of applications. Thermoplastics provide your project with the following benefits:

- Chemical resistant

- Eco-friendly manufacturing options

- Electrical insulation

- Elimination of lubrication

- Faster operation of equipment/ line speeds

- High strength and rigidity

- Impact resistance

- Less power needed to run equipment

- Longer part life

- Low coefficient of friction

- Low dissipation factor

- Low moisture absorption

- Reduced wear on mating parts

Thermosets

At K&E, we machine all types of composite grades including fiberglass-reinforced polyesters, paper-based laminates, and glass fabric laminates to name a few.

Why use thermosets? They are the perfect option for applications demanding the following capabilities:

- Economical

- Electrical insulation

- Excellent wear properties

- Flexible design

- Heat-resistant

- Lighter weight ratio than metal

- Superior dimensional stability

K&E cutting-edge technology brings your ideas to life at the level of quality your project demands. GET A K&E QUOTE

Copyright 2018. All Rights Reserved. Privacy Policy